GridShell Arbour presents a full scale prototype of our developed GridShell System – a 3D-printable parametric system inspired by Australia’s coral reefs.

Fuelled by a desire to represent their love of architecture and parametric design at their wedding, our directors Andrew and Suzy designed the prototype to take the form of an arched arbour that took centre stage during their celebrations in September.

Location

Roaming Installation

Status

Complete 2023

Gross Floor Area

2sqm

GridShell Arbour

CONCEPT

Our GridShell concept takes inspiration from Australia’s beautiful coral reefs; with awareness of the devastating effect climate change and pollution have had on reefs and ocean-life at large. Keeping in mind the desire to create a 3D printable, adaptable shell system, the system’s cell forms combine natural patterns of differential growth with a logical triangular grid to form a biophillic cellular grid shell system reminiscent of bleached coral formations.

The Arbour’s arched form was envisioned at a scale that would neatly wrap around two people standing side by side, utilising double curvature to give the necessary strength to the triangulated gridshell structural system, as well as form finding analysis to predict gravity induced compression and form distortion of the arch.

CREATION

The GridShell system required a highly complex parametric script capable of ‘growing’ a discernibly organic form within a controlled cellular structure capable of wrapping any defined shell-like surface. All elements of the parametric system, from biophilic cell growths to the wholly unique printable three-way joint system, are created and controlled by the script to provide full parametric control – with just the base shell surface inputted.

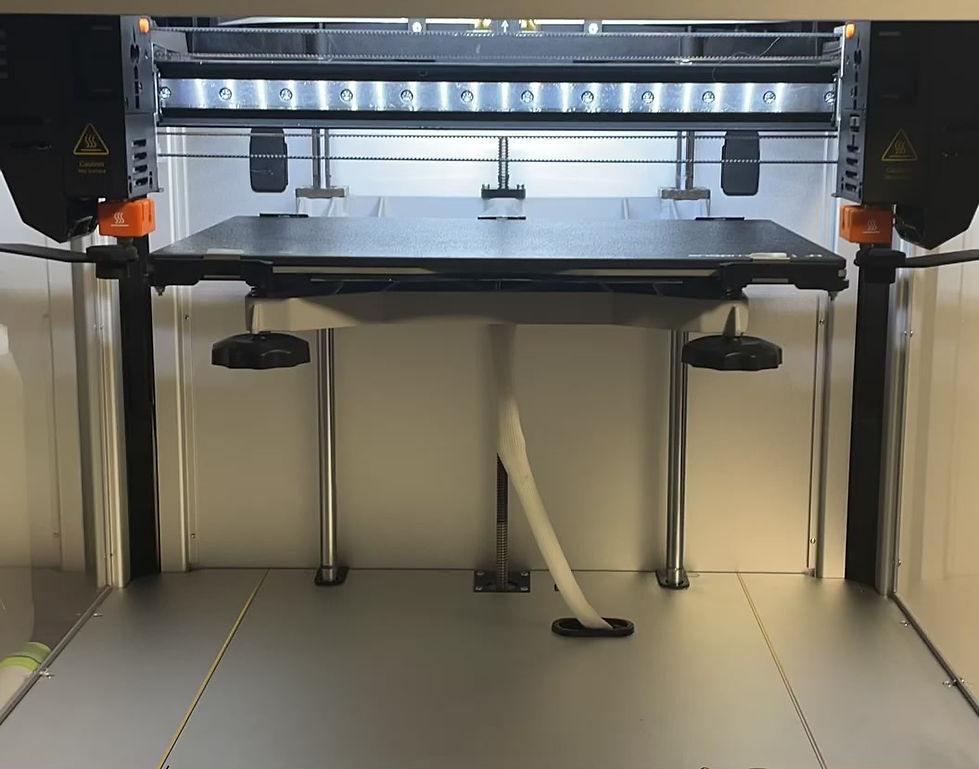

Prototyping was paramount to the eventual success of the GridShell system; taking a complex scripted design concept to a constructible, self-supporting cellular shell system printable on any fused deposition 3D printer and requiring only basic fixings (screws) to assemble. Early print runs identified areas of issue with the printing process itself that were quickly remedied, followed by comprehensive testing of the system joints and strength of the assembled cells that led to a refined system capable of assembly at a human-occupiable scale.

While we envision future real-world potential of the GridShell system in forming structures of a grander scale, the successful fabrication and assembly of the Arbour proudly proved the feasibility of the GridShell system as a self-supporting 3D printable structure, whilst forming a stunning centerpiece for our wedding celebrations.

SUSTAINABILITY

We believe that true sustainable practice, should consider life beyond the briefed form of the project, both as a whole as well as the broken-down elements of its assembly. As such, we wanted the GridShell Arbour to be inherently sustainable in all elements of assembly, in conjunction to having a rich life beyond its initial planned purpose as the arbour for our wedding.

As a base line of sustainable practice, we used recycled filament to print the 172 cells and 4 ‘feet’ comprising the arbour and sourced a beautiful plank of locally culled Camphor Laurel - an invasive species in Australia - to form the sturdy base. Prototyping inevitably creates a trail of fabricated parts that will not be used in the final assembly; in order to eliminate waste we adopted a dual approach wherein full cell prints were gifted to special wedding guests as a memento of the occasion and their contributions, and failed prints alongside extruder excess were carefully collected throughout the printing process to be turned back into recycled filament, as well as dissolved into filament slurry for use as required.

Initially, the Arbour will find life beyond the wedding in its current form at exhibitions and events. When we ‘retire’ the full Arbour the cellular arch will be reconfigured into a series of three wall and ceiling light features in our home/studio. Whilst the base timber plank, chosen for its 1.8m x 0.9m dimensions and aesthetic properties, has been carefully connected wrong-side up to the arbour feet to leave the right-side uncompromised and will be crafted into our dining table when the time comes.